Koneosapalvelu offers a unique comprehensive service for loader cranes used in industrial wood processing lines. We offer all the necessary components, from timber cranes to hydraulics, and we handle the project as a total delivery, from design to installation and documentation in accordance with the Machinery Directive. We manufacture e.g. hydraulic power units, directional valves, control systems and grapples. We don’t need a complex subcontracting network to deliver the project, because in addition to our own production, we have competent salespeople, designers, installers and authorized lifting equipment inspectors.

We serve nationwide in the modernization, repair and maintenance of loader cranes and related hydraulics in the wood processing industry. Read more about our service below and contact our industrial sales, and we will offer a customized, efficient solution for wood processing equipment.

We look forward to serving you with our crane and hydraulics expertise

Watch the video of the implementation of a crane project

You will find more videos on our YouTube channel.

Work flow and components of a crane project

Technical specifications and project planning

We start the crane project with a careful scan of the project scope together with the customer. In the preliminary investigation, we check the components to be replaced or refurbished and define the specifications that guide the design of crane selection, control system modules, hydraulic power unit, mounting plate, electrification and automation.

When acquiring a new loader crane, we are not tied to a specific manufacturer, but we deliver the crane that best suits the customer’s needs. We offer the required crane inspections for used cranes. We also recondition used cranes with the help of our own workshop and cylinder repair shop. We can manufacture the mounting plates needed for the cranes in our workshop. We take care of the necessary demolition work, liftings and logistics.

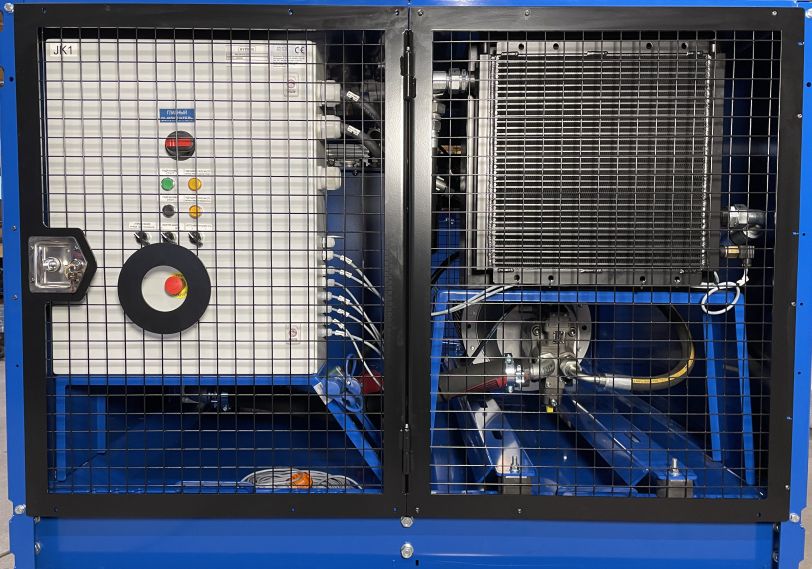

Manufacturing of hydraulic power units, valves and control system

For the use and control of cranes, we offer HYPROX® hydraulic power units, Parker directional valves and IQAN control systems. We have a long experience in the design and assembly of hydraulic power units tailored for demanding industrial use, which we utilize in the manufacture of compact power units especially suitable for timber loading systems.

Koneosapalvelu is a sertified Parker Distributor Mobile Technology Centre. We design optimized valve solutions for a range of applications using the eSyber programme. Our extensive valve component warehouse means we deliver fast. We carry out the assembly work in our modern hydraulics repair shop premises and test drive valves using our own testing machinery. We design the IQAN control system with the IQAN Design programming tool to the customer’s specific needs. We choose the most suitable components, assemble the system using tailored cable sets and always test the control system before delivery.

Vahva grapples with the special jaws for industrial use

Completing the crane boom, our product range includes VAHVA grapples designed for wood processing, as well as Baltrotors rotators and links. The Vahva grapple has been Koneosapalvelu’s own product since the 1980s. We manufacture the smallest Vahva B15 model with special jaws tailored for industrial use. The special jaws with a sharp triangular tip ease the handling of single logs, so the model is especially suitable for sawmills and other wood processing lines.

Installation, test runs, training and documentation

During the installation phase, if necessary, we put in place a new crane mounting plate, a new and/or refurbished crane, grapple, directional valve, hydraulic power unit, control devices and other possible equipment, as well as all necessary hydraulic hoses, tubes and cables. Our installers, who specialize in industrial installations and hydraulics, carry out the work promptly within the schedules required by maintenance shutdowns, without compromising on safety. After the installations are completed, we perform test runs.

Of course, our overall delivery also includes the necessary commissioning inspections, user training, project management work and documentation, the content of which is defined together with the customer during the project planning phase.