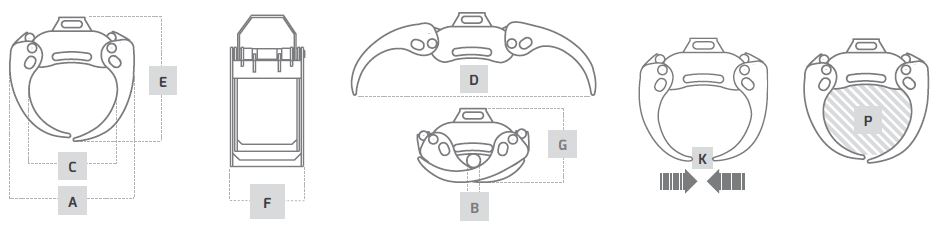

The Vahva E models have spikes instead of traditional log jaws, and they have been designed for handling logging residues, stumps, and other materials in the recycling industry. These so-called bioenergy grapples are suitable for use e.g. with forwarders and chippers. The E models are available with 4, 5, 7 or 9 spikes. In model markings, the number after the letter “E” indicates the amount of spikes, e.g. the C42 E5 grapple has five spikes.

There are six different models in the E series made with the C-frame and, in addition, the smallest 15-model with an older B-frame structure. We manufacture the smallest B15 model also with special jaws tailored for industrial use. Special jaws with a sharp triangular tip facilitate the handling of individual logs. The model is suitable for sawmills and other wood processing lines. Spike grapples suitable for excavators can be found in the KC series.

Vahva grapples are designed and manufactured at the very modern forestry attachements factory of Outokummun Metalli Oy in Finland. The high quality level is demonstrated by, for example, high-strength steel as material, robotic welding, machined peg lines, bronze bearings and powder coating. The spikes of all of the E models are made of HARDOX 400 wear- and abrasion resistant steel. This ensures that the spikes can handle wear and tear even in challenging use. All of our grapples (except 15 and 21) have two reaction links, which means that the mechanics are symmetrical and torques have been minimised.

Greasing of the grapple is safely performed in one position while the grapple is closed and lowered to the ground. The open frame structure of the grapple facilitates hydraulic hose maintenance.

Technical specifications, Vahva E models

| Model | Weight (kg) |

Area (m²) |

Max. operating pressure (bar) |

Max. load (kg) |

Gripping force, tip (kN) |

A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B15 E4* | 102 | 0,15 | 175 | 2000 | 7,5 | 725 | 80 | 535 | 1215 | 735 | 290 | |

| C21 E4 | 146 | 0,21 | 240 | 3000 | 9,4 | 783 | 90 | 513 | 1320 | 750 | 427 | 485 |

| C30 E4 | 297 | 0,30 | 250 | 4000 | 19 | 955 | 70 | 655 | 1780 | 978 | 525 | 592 |

| C36 E7 | 360 | 0,36 | 250 | 4000 | 19 | 955 | 70 | 655 | 1780 | 978 | 625 | 591 |

| C42 E5 | 470 | 0,42 | 250 | 6000 | 23 | 1130 | 165 | 840 | 1955 | 1125 | 850 | 702 |

| C42 E9 | 610 | 0,42 | 250 | 6000 | 23 | 1130 | 165 | 840 | 1955 | 1125 | 850 | 700 |

| C46 E4 | 450 | 0,46 | 250 | 6000 | 23 | 1180 | 130 | 910 | 2000 | 1212 | 595 | 679 |

| The manufacturer reserves the right to make changes in technical specifications. *The model B15 E4 is part of the older B series. |

||||||||||||

Watch the video: Vahva C46 E4 with a Ponsse Buffalo handling logging residue

You will find more videos on our YouTube channel.

How can we help?

+358 20 755 1240

info@koneosapalvelu.fi

All contact details