The frame of the grapple has been designed to be bended and symmetric, keeping stresses under better control. The cylinder uses both jaws, and the reaction links stabilise the movement. All of our grapples (except 15 and 21) have two reaction links, which means that the mechanics are symmetrical and torques have been minimised.

The tips of the jaws are designed to get into the pile at an optimal angle and grab a full load when they close. Special focus has been placed on the effectiveness of the jaws in handling pulpwood. When lifting, the tree trunks straighten easily thanks to the structure of the jaws and the base of the frame and the appropriate compression force. Wide opening of the jaws makes working easier.

Ease of maintenance has also been taken into account in the design. Greasing of the grapple is safely performed in one position while the grapple is closed and lowered to the ground. The open frame structure of the grapple facilitates hydraulic hose maintenance.

Vahva grapples are designed and manufactured at the very modern forestry attachements factory of Outokummun Metalli Oy in Finland. The high quality level is demonstrated by, for example, high-strength steel as material, robotic welding, machined peg lines, bronze bearings and powder coating.

The C line also includes three HD (Heavy Duty) models: C36HD, C46HD, and C60HD. The frame and jaws of the HD models are designed for particularly challenging applications, like for large forwarders. Compared to the basic models there is e.g. a thicker cover plate and thicker side plates with longer welds in the frame of the HD models.

The three biggest grapples of the Vahva C series, C60HD, C80 and C100, are primarily designed for material handling machines. The models used in loading terminals bring efficiency to the processing of large quantities of timber.

Read more about the grapples suitable for material handlers.

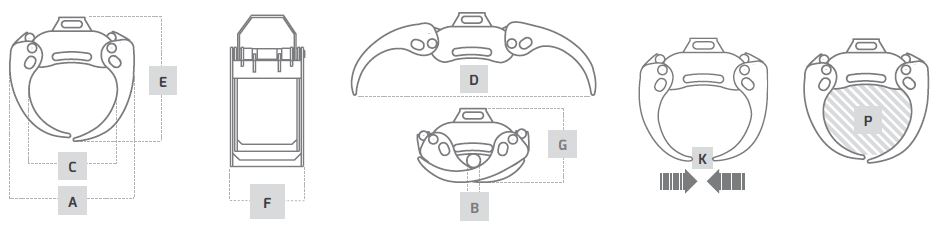

Technical specifications | Vahva C models

| Model | Weight (kg) |

Area (m²) |

Max. operating pressure (bar) |

Max. load (kg) |

Gripping force, tip (kN) |

A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B15* | 89 | 0,15 | 175 | 2000 | 7,5 | 725 | 80 | 535 | 1215 | 735 | 325 | 485 |

| C21 | 120 | 0,21 | 240 | 3000 | 9,4 | 820 | 90 | 570 | 1345 | 799 | 368 | 492 |

| C26 | 230 | 0,26 | 250 | 4000 | 19 | 940 | 95 | 605 | 1600 | 888 | 473 | 604 |

| C30 | 235 | 0,30 | 250 | 4000 | 19 | 960 | 95 | 665 | 1690 | 940 | 475 | 599 |

| C36 | 242 | 0,36 | 250 | 4000 | 19 | 1005 | 95 | 765 | 1770 | 995 | 475 | 592 |

| C36HD | 296 | 0,36 | 250 | 4000 | 19 | 1005 | 95 | 765 | 1770 | 995 | 506 | 592 |

| C42 | 290 | 0,42 | 250 | 6000 | 23 | 1115 | 130 | 810 | 2010 | 1110 | 535 | 672 |

| C46 | 300 | 0,46 | 250 | 6000 | 23 | 1130 | 130 | 840 | 2010 | 1130 | 535 | 666 |

| C46HD | 390 | 0,46 | 250 | 6000 | 23 | 1130 | 130 | 840 | 2000 | 1130 | 566 | 665 |

| The manufacturer reserves the right to make changes in technical specifications. *Model B15 is part of the older B-series. |

||||||||||||

Videos

Watch the latest videos of Vahva C models. You will find more videos on our YouTube channel.

How can we help?

+358 20 755 1240

info@koneosapalvelu.fi

All contact details